The knowledge and technology lead of Robooptic Systems is based on more than 20 years of experience in special purpose machine manufacturing.

|

1998 Establishment of the engineering office for constructive consulting, support and planning in special machine construction in Klagenfurt. |

|

|

1999 We started developing products for Philips in Vienna back in 1999. Our first project focused on the development of the RGB alignment station for the production of a 3-LCD projector. |

|

|

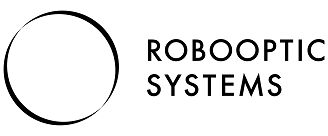

2003 Since then we have been dedicated to the development of machines for the production of mechanical, optical devices such as projectors and 3-CCD cameras. Through our own research and experimental set-ups we have been able to develop continuously in this field.

|

|

|

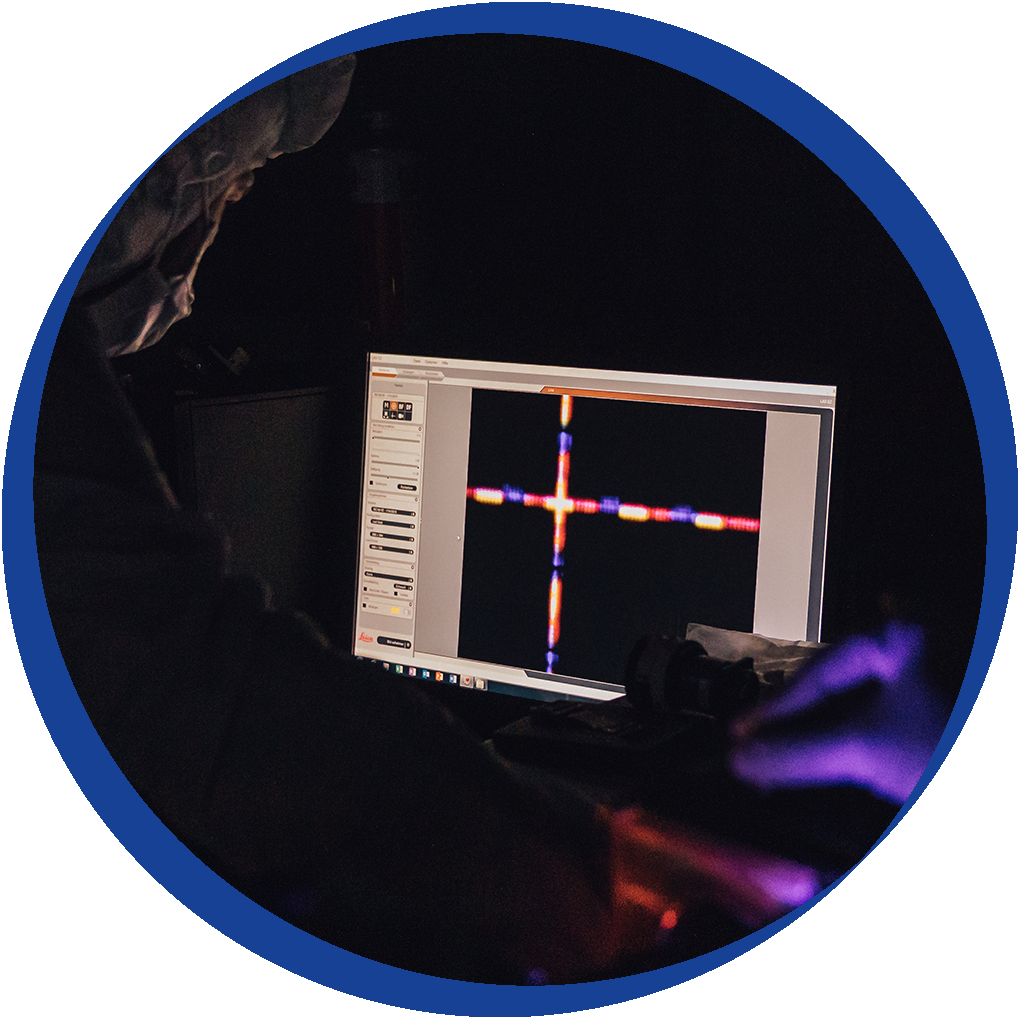

2006 Installation of a dedicated clean-room to better assist customers in process development and to support small-series production. This allowed for prototype systems to be tested under clean-room conditions and the installation of the clean-room enabled us to carry out our first projects in medical technology. Projector and 3-CCD camera systems for surgical applications could be developed under clean-room conditions. Planning, construction and delivery of the first assembly line for cinema projectors with laser light sources.

|

|

|

2010 Relocation to the new premises at the Waidmannsdorferstraße in Klagenfurt with its own CNC machine workshop in the company. Front headlamps in the automotive industry increasingly resemble a projector with laser light source. Thanks to this development we were able to prove ourselves in first projects in this field and deliver our first fully-automatic assembly line to the automotive industry.

|

|

|

2013 In close collaboration with our customers, we have proven ourselves in the field of process development of manufacturing methods for optoelectronic components. With new possibilities for precision assembly, we now offer our customers additional services to secure production processes in addition to process development.

|

|

|

2016 As a result of the transition to Industry 4.0, more and more processes are being automated in the metal industry as well. We were able to deliver one of the first production lines for the metal industry with fully-automatic, optical surface inspection in the hundredth of a millimetre range.

|

|

|

2018 The GAW Group acquires 65 % of the company's shares and supports its growth through its global service network. As a strategic partner, GAW offers a wide range of manufacturing solutions and special machines for the automotive industry. From conveying and painting technology, fixture construction and assembling to steel construction and application technology make the company a reliable partner with many years of experience. Customers include the Volkswagen Group, Magna, ABB, AVL, Jenbacher Motorenwerke, Palfinger, ZF and others. |

|

|

2020 Renaming of M-Tech Systems GmbH to Robooptic Systems GmbH and strategic focus on core competencies. |

|